Diamond Cutting: Precision Techniques for Masterful Brilliance

Diamond cutting is an art that transforms rough stones into brilliantly faceted gems. The process is a blend of engineering precision and creative expression. As a diamond cutter, I consider myriad factors to enhance the stone's natural beauty and maximize its value. The knowledge and tools required for diamond cutting have been honed over centuries, with each facet cut contributing to the diamond's ability to refract and reflect light, resulting in its characteristic sparkle.

Table Of Contents

- History and Evolution of Diamond Cutting

- The Science of Diamond Cutting

- Diamond Cutting Techniques

- Diamond Cut Styles and Shapes

- Factors Affecting Diamond Value

- Cutting Process and Diamond Anatomy

- Evaluating and Grading Diamond Cuts

- The Future of Diamond Cutting

- Diamond Cutting Around the World

- Buying Tips for Cut Diamonds

- The Artistry of Diamond Cutters

- Technical Aspects of Cutting Diamonds

- Frequently Asked Questions

The journey begins with the careful assessment of the rough diamond to determine the best possible cut. This stage is crucial as it dictates the yield, shape, and potential brilliance of the finished gem. My techniques involve mapping the stone, factoring in the crystallographic structure, to identify the directions of potential cleavages and inclusions, which can affect the durability and aesthetic of the final product.

Success in diamond cutting hinges on precise execution. Each angle and each facet must conform to exacting standards, as the cut directly impacts the diamond's brilliance, fire, and overall appearance. The mastery of the cutting equipment, the thoughtful interpretation of the diamond's unique properties, and my steady hand all come together to create a stone that not only tells a tale of the Earth's history but also carries the legacy of a craft perfected over generations.

History and Evolution of Diamond Cutting

Diamond cutting has a rich history, characterized by artistic and technological transformations. My focus here is to trace the lineage of this craft, spotlighting key people and innovations that shaped the diamond industry.

Early Techniques

India is the earliest known source of diamonds, and the initial style of cutting was rudimentary. The primary method involved simple cleaving or splitting along the diamond's natural lines of weakness. Initially, diamonds were left in their natural octahedral shape or were slightly reshaped to refine their appearance. This technique emphasized the preservation of the diamond's size rather than maximizing its brilliance.

By the 14th century, the craft had spread to Europe. A guild of diamond cutters was established in Nuremberg, Germany around 1375, signifying a more systematic approach to cutting. The first efforts into cutting facets on diamonds began with the point cut, which followed the crystal's natural shape.

Technological Advances

As techniques evolved, diamond cutting began incorporating more complex facets and shapes. Sawing, another pivotal technique, emerged, allowing cutters to slice through diamonds with greater precision. I understand from a notable point in history around the early 1870s, when the bruting machine was invented by Henry D. Morse and Charles M. Field. This innovation automated the shaping of the diamond, greatly enhancing the efficiency and precision of cutting.

The early 20th century saw the birth of the modern round brilliant cut, pioneered by Marcel Tolkowsky in 1919. His designs were based on mathematical calculations to maximize brilliance and fire in the diamond. The round brilliant cut remains one of the most popular and sophisticated cuts in the world.

Significant Figures in Diamond Cutting History

Several significant figures have left their mark on the diamond cutting industry. Among them, Hentry Grossbard revolutionized the craft in 1977 by introducing the radiant cut. He combined the emerald cut's shape with the brilliance akin to that of round cuts, eventually settling on a 66-facet pattern.

The Royal Asscher Diamond Company was also a key player, responsible for inventing the iconic Asscher cut in 1902. This cut featured a distinctive square shape with large, stepped facets, and didn't gain popularity until decades later. These individuals and companies represent just a fraction of those who've contributed to the sophisticated craft of diamond cutting, shaping the industry into what it is today.

The Science of Diamond Cutting

Cutting a diamond is an intricate balance of art and meticulous engineering. I'll explore the interplay between a diamond's natural characteristics and the precise techniques used to unveil its hidden beauty.

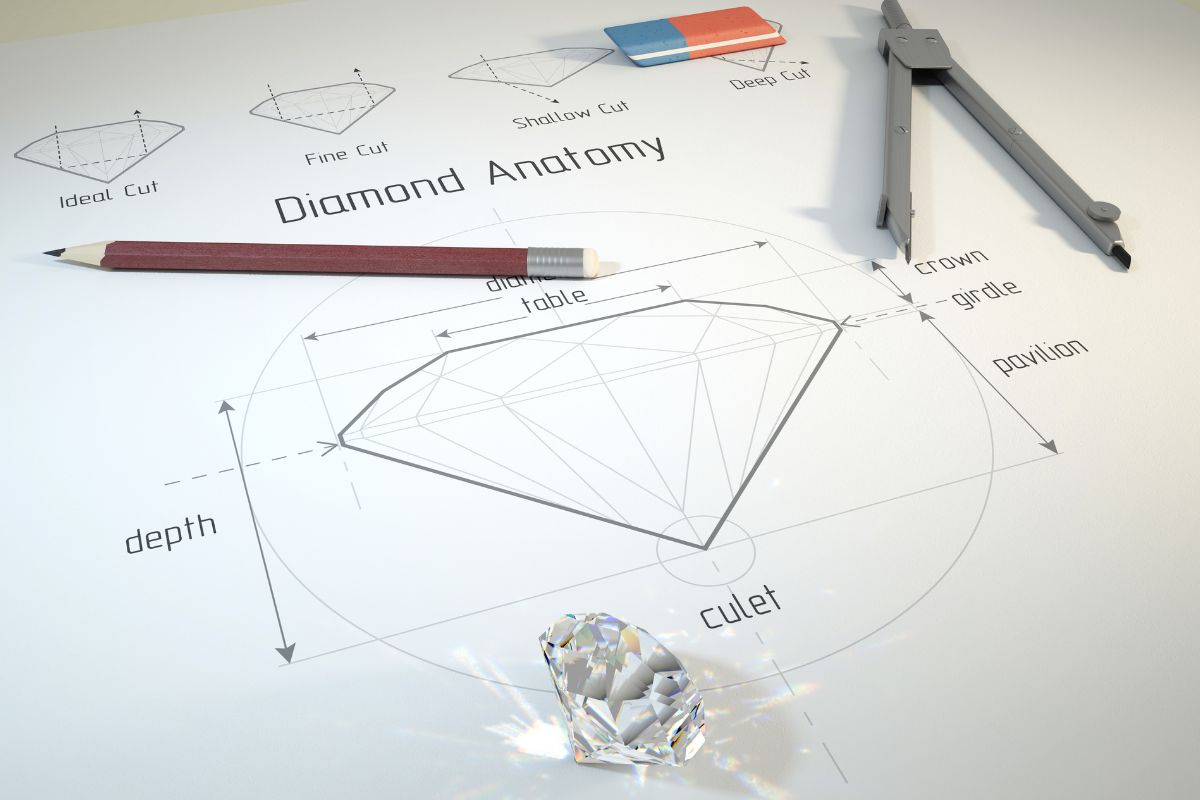

Understanding Diamond Anatomy

Before I begin cutting, I must thoroughly understand the diamond anatomy. Each diamond consists of several parts including:

- Girdle: The widest edge of the diamond where the crown (top) meets the pavilion (bottom).

- Crown: The upper part of the diamond, which is visible once set in jewelry.

- Pavilion: The lower portion of the diamond, below the girdle, which culminates at the tip or culet.

Facets, which are the flat surfaces on geometric shapes, are cut into these areas to optimize the diamond's brilliance and fire.

The Role of Crystallography in Cutting

Diamond cutting heavily relies on crystallography. Diamonds are cut along the crystal's natural planes, which are determined by the diamond's molecular structure. I consider these factors:

- Crystal Shape: Impacts the potential cut and shape of the gem.

- Grain and Angles: Similar to the grain in wood, diamonds have grains that I must consider to prevent potential splitting during cutting.

The positions of facets must align with the crystal's grain for optimal light reflection and symmetry.

Physical and Optical Properties

When assessing physical and optical properties, I consider:

- Carat: Denotes the diamond’s weight where higher carat means a larger diamond, providing more room for a more intricate cut.

- Symmetry and Proportions: Key for the diamond's light performance—how the light is reflected inside the gemstone.

- Reflection and Light Return: Affects the brightness and how the sparkles are distributed across the diamond.

Careful calculation of angles and proportions ensures the balance of maximum light return and aesthetic appeal of the gemstone.

Diamond Cutting Techniques

Diamond cutting is a meticulous process that demands precision and care at every stage. I'll take you through the core methods used in shaping these gems into their brilliant final forms.

Planning the Cut

Before any physical work begins on a rough diamond, it's vital to thoroughly plan the cut. I start by examining the crystal structure to mark the best possible approach to maximize carat weight and enhance the gem’s natural brilliance. Specific cuts are strategized to reduce flaws, optimize light refraction, and increase the stone's value. In this planning phase, I harness my expertise to foresee the end-result before a single facet is formed.

Cleaving and Sawing

Once I've marked a diamond, it's ready for separation into smaller, more manageable pieces – a process known as cleaving. For diamonds that cannot be cleaved, I use a diamond saw, which is a precise blade impregnated with diamond dust. The decision between cleaving and sawing depends on the rough diamond's crystal structure. Either way, precision is crucial here, as even a minor miscalculation can result in significant loss of material or potential value.

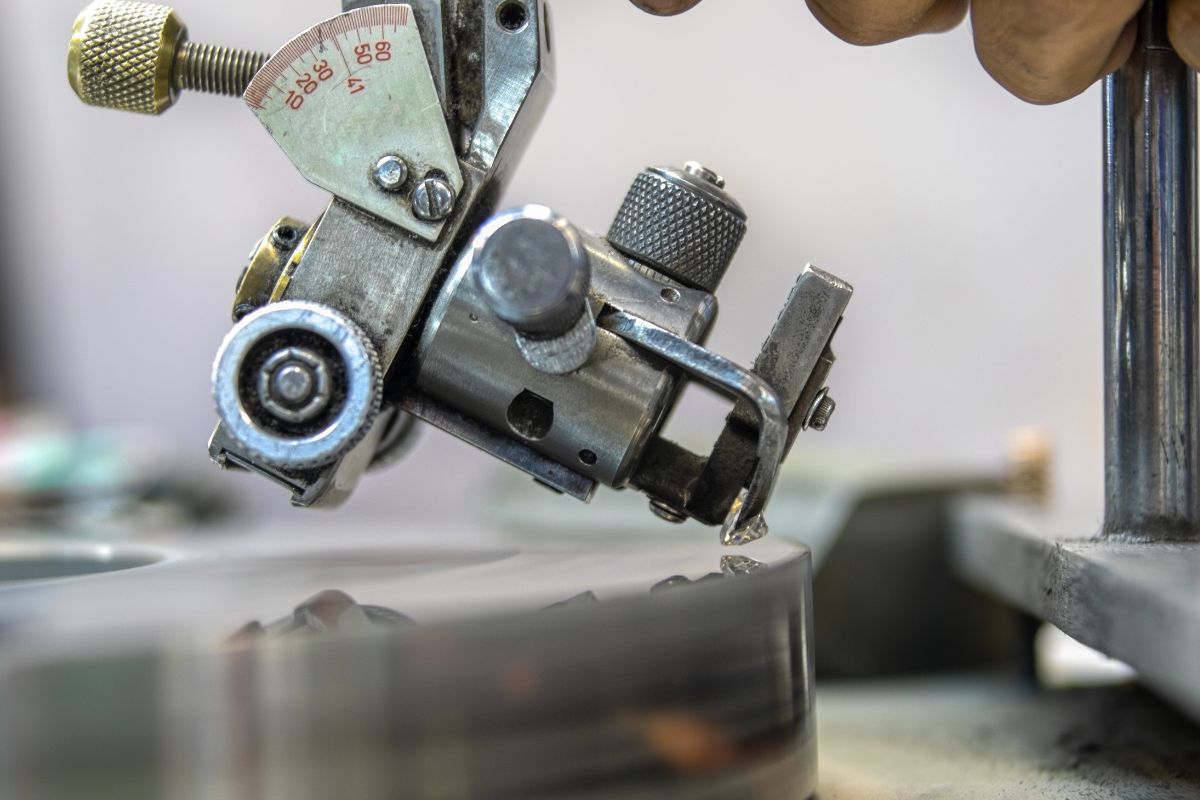

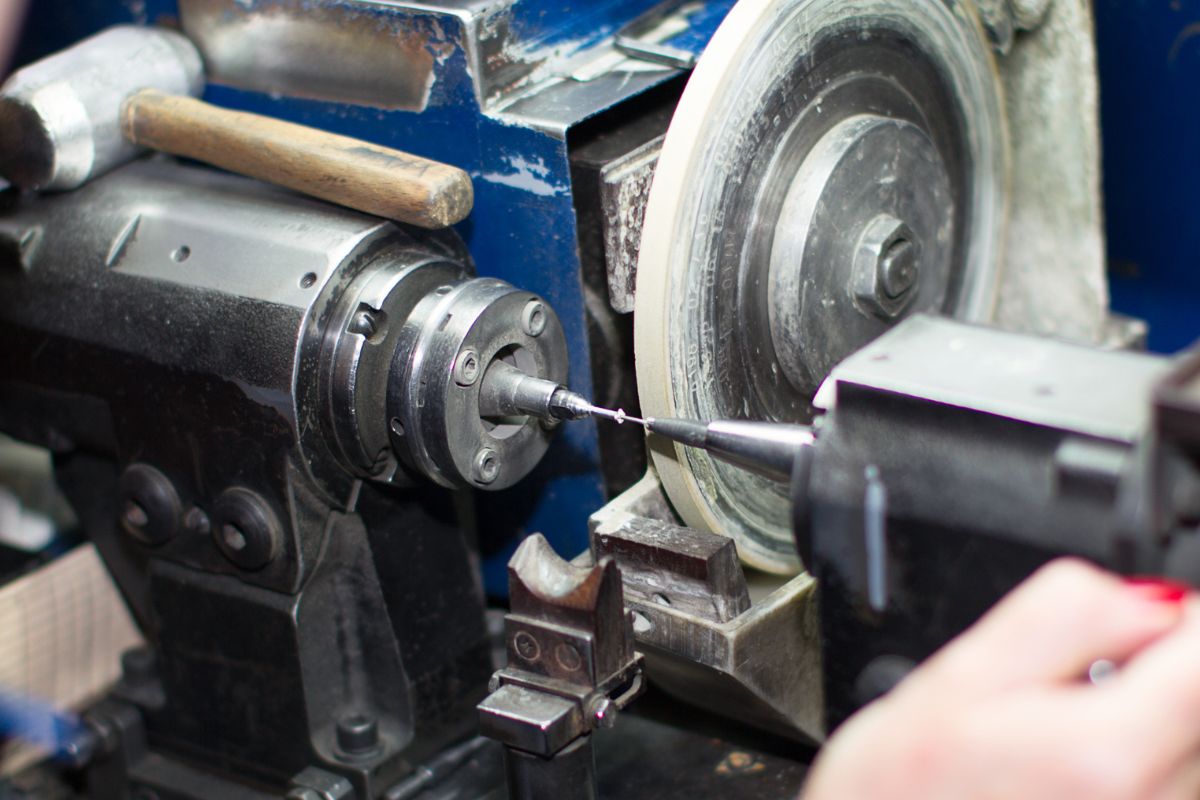

Bruting and Polishing

After the rough diamond has been divided, it moves onto bruting, where two diamonds are set on spinning axles turning in opposite directions to grind against each other. This achieves the basic rounded shape of the diamond. Then comes polishing, where the use of a spinning wheel coated with a fine abrasive diamond powder is employed to craft each individual facet. I must maintain a steady hand and vigilant eye during faceting, as this is what defines the diamond's intricate interplay with light.

Final Inspection

In the last checkpoint, each diamond undergoes a rigorous inspection process. I scrutinize every angle to ensure that the cut meets the highest standards of craftsmanship. This final evaluation ensures that each facet is symmetrical and the polish is flawless, ensuring the desired brilliance and scintillation are achieved. Only then can the diamond be considered finished and fit to be set into a piece of jewelry or sold as a loose gem.

Throughout these steps, my focus on precision and a disciplined adherence to the diamond cutting process are what allow me to transform these rough stones into treasured works of art.

Diamond Cut Styles and Shapes

Diamond cuts and shapes are fundamental to the beauty and value of these gemstones. I'll discuss the variety of cut styles and the aesthetic attributes they contribute to the overall appearance of diamonds.

Traditional Cuts

- Round Brilliant: This is the most popular diamond shape and boasts 58 facets, providing exceptional brilliance and fire. The round cut maximizes light return more efficiently than other shapes.

- Emerald: Known for its step-like facets and rectangular shape, it provides a hall-of-mirrors effect rather than fiery brilliance. The emerald cut highlights clarity over sparkle.

- Oval: An elongated version of the round cut, maintaining similar brilliance. The shape can enhance the perceived size of the diamond, making it appear larger.

- Marquise: With its football-like shape, this cut creates the illusion of greater size. It has a brilliant facet pattern that brings ample sparkle.

- Pear: Combining the qualities of round and marquise shapes, the pear cut also gives a slenderizing effect to the finger when set in rings.

- Cushion: This cut has rounded corners and larger facets to increase its brilliance. The cushion cut combines a square cut with rounded corners, much like a pillow (hence the name).

Fancy Cuts

- Princess Cut: A square modified brilliant cut with pointed corners, highly regarded for its fire and scintillation. It can be square or slightly rectangular in shape.

- Heart Shape: Often chosen for symbolic meanings, this cut requires great skill to ensure balance and avoid clefts that are too sharp or wings that are too flat.

- Fancy Cut: Any cut that is not a round brilliant can be classified as a fancy cut. These cuts emphasize unique shapes and often focus on maximizing carat weight.

Cut Quality and Styles

- Brilliant Cut: This style aims to maximize light return. A well-executed brilliant cut can dramatically enhance the diamond's sparkle.

- Cut Quality: Diamonds are graded based on cut quality, which impacts their interaction with light. Grading ranges from Excellent to Poor. An Excellent cut grade reflects optimal proportions and facet precision.

Cut styles significantly influence the final appearance and brilliance of a diamond. My aim was to elucidate the distinct characteristics of different styles and shapes that govern their appeal.

Factors Affecting Diamond Value

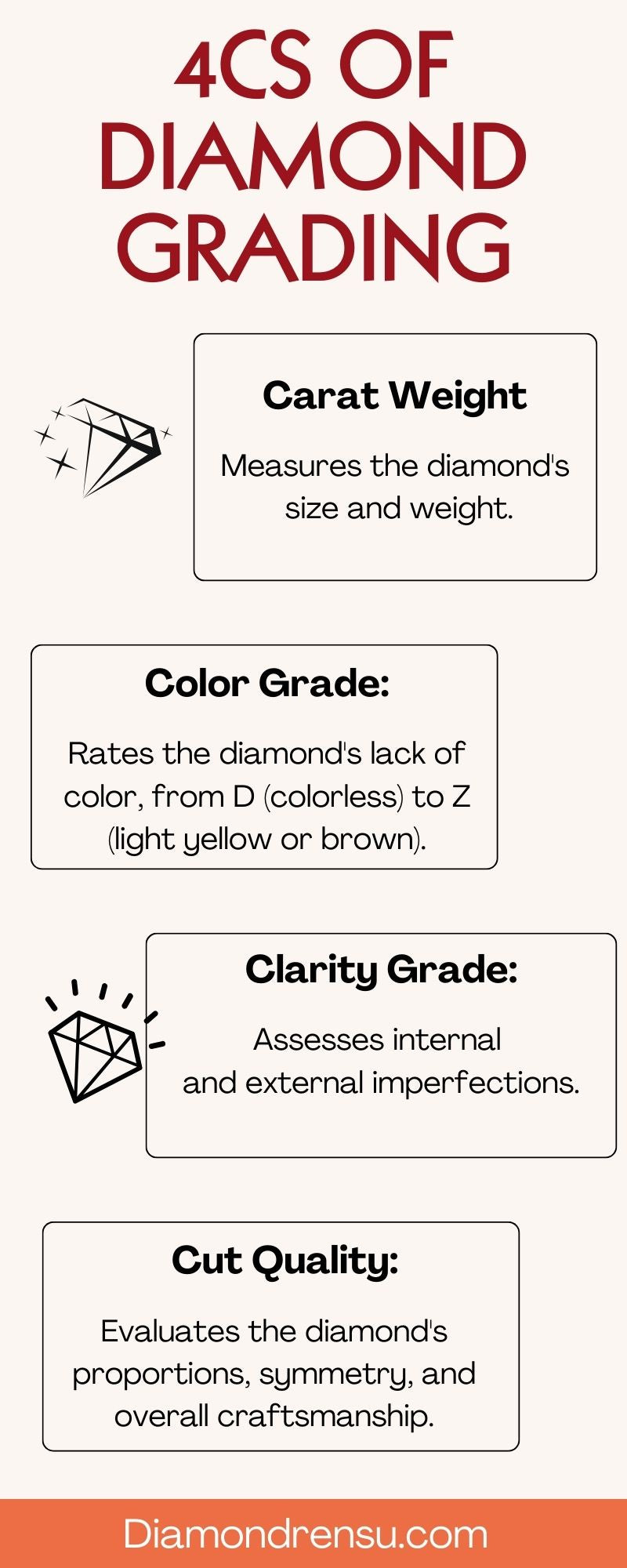

As an expert in the field, I must emphasize that the value of a diamond is predominantly determined by the Four Cs: Carat, Color, Clarity, and Cut. Each of these elements plays a crucial role in evaluating a diamond's worth.

The Four Cs: Carat, Color, Clarity, Cut

- Carat: A diamond's weight is measured in carats and naturally affects its value; the larger the diamond, the more it typically costs.

- Color: The Gemological Institute of America (GIA) grades diamond color on a scale from D (colorless) to Z (light yellow or brown). Diamonds closer to colorless are usually more valuable.

- Clarity: This refers to the absence of inclusions and blemishes. Clarity is graded from Flawless to Included. The fewer the imperfections, the higher the clarity grade, and consequently, the higher the value.

- Cut: Of the Four Cs, cut has the greatest effect on a diamond's beauty. It determines the stone's symmetry, proportions, and ability to reflect light, which are crucial for its sparkle, fire, and brilliance.

Cut Grade and Performance

The GIA cut grading system ranks diamond cut quality from Excellent to Poor. A diamond with an Excellent cut grade assures optimal brilliance and sparkle due to its high cut quality. The performance of a diamond relates directly to its cut grade. A well-cut diamond, such as a round brilliant with an Excellent cut, will display superior fire and brilliance.

Market Preferences

Cut quality greatly influences market preference. Round brilliant diamonds with high cut grades are in high demand due to their remarkable brightness and beauty. However, fancy cuts are also popular and exhibit unique fire and brilliance. The predominant consumer preference leans towards diamonds that display an exceptional balance of sparkle, fire, and brilliance which all stem from high cut quality.

Cutting Process and Diamond Anatomy

| Stage | Description |

|---|---|

| Planning | Initial assessment and design planning. |

| Cleaving | Initial separation of rough diamond into smaller pieces. |

| Sawing | Cutting the diamond into basic shapes. |

| Bruting | Shaping the diamond into a round form. |

| Faceting | Precision cutting of facets for brilliance and fire. |

| Polishing | Final polishing to enhance shine and clarity. |

| Inspecting | Detailed examination to ensure quality and precision. |

I'll guide you through the meticulous art of diamond cutting and its significance in defining the anatomy of a diamond.

The Cutting Procedure

When I approach diamond cutting, my primary concern is to enhance the stone's natural brilliance. This involves a precise and calculated process where each diamond is analyzed to maximize its potential. Faceting is a key step, which includes carefully polishing each facet of the diamond to reach an exact size and angle that ensures optimal reflection and refraction of light. The main goal is to achieve a balance between maximum brilliance and the diamond's inherent carat weight. The procedure involves creating multiple facets: the table, crown, pavilion, girdle, and culet.

Anatomical Features of Diamonds

Each part of a diamond's anatomy plays a crucial role in its appearance. The table is the flat surface at the top and it is the largest facet of a diamond. Around the table is the crown, which consists of kite-shaped and star facets that help direct light into the diamond. The girdle is the narrow rim that defines the circumference and acts as the dividing line between the crown and the pavilion (the lower portion of the diamond). Precise cutting of the pavilion's facets is essential as they reflect light from one side to another before directing it back through the top of the diamond. Lastly, the culet is a small facet at the bottom of the pavilion, intended to prevent chipping.

Innovations in Cutting Design

As I explore modern diamond cutting techniques, advancements in technology have introduced tools that enable precision at levels previously unattainable. Laser cutting allows me to outline the diamond with extreme accuracy. Computer programs aid in creating facet patterns that optimize light performance. Newer cuts and shapes are continually being created, offering unique fire, brilliance, and character, while novel faceting patterns increase the ways in which diamonds can capture and reflect light.

The evolution of diamond cutting tools and techniques continuously influences the way I handle the natural resource, leading to a diverse array of diamond shapes and appearances that cater to different tastes and design requirements.

Evaluating and Grading Diamond Cuts

In evaluating and grading diamond cuts, I consider precision and craftsmanship to be paramount for ensuring that a diamond's light performance maximizes its fire, brilliance, and scintillation.

Diamond Cut Grading Systems

Modern grading systems assess the cut of diamonds in comprehensive detail. The most recognized among these is the grading system developed by the Gemological Institute of America (GIA). This system grades diamonds on a scale from Excellent to Poor, taking into account factors like brightness, fire, scintillation, weight ratio, durability, polish, and symmetry. The GIA system set a globally accepted standard for how diamond cuts should be evaluated.

- Excellent: Represents top-tier quality in cut, allowing for maximum light performance.

- Very Good: Slightly less precise than excellent cuts but still allowing for high light return.

- Good: Adequate light return with much less precision required in the cutting process.

- Fair: A cut which allows light to escape from the sides and bottom, reducing perceived sparkle and fire.

- Poor: Cuts that permit much of the light to escape from the bottom and sides.

Assessment of Cut Quality

The quality of a diamond's cut is determined by how well the facets interact with light. Precision in the angles and finish of each facet affects how light travels within the diamond and how it exits in the form of reflected light.

Key Factors in Cut Quality:

- Symmetry: Refers to the alignment of the diamond's facets.

- Polish: Denotes the smoothness of each facet's surface.

- Angles and Proportions: Including depth percentage and table size which dictate how light reflects within the stone.

- Crown and Pavilion Angle: Must be optimal to ensure the stone's fire and brilliance.

The depth percentage and table size are crucial. For example, a depth percentage too deep or shallow can lead to a diamond that loses more light through the sides or bottom.

Impact on Light Performance and Aesthetics

The ultimate aim of a diamond cut is to enhance the diamond's light performance, which consists of:

- Brilliance: The total light reflected from a diamond.

- Fire: The dispersion of light into the colors of the spectrum.

- Scintillation: The pattern of light and dark areas and the flashes of light, or sparkle, when a diamond is moved.

- Pattern: Refers to the arrangement of a diamond's facets.

Each of these qualities is intrinsically linked to the precision of the cut. A well-cut diamond will demonstrate a balance between brightness and fire, which is achieved by the interplay between its table size, crown angle, depth, and other facets. Girdle thickness and pavilion depth also play a role, influencing the angle at which light exits the stone, contributing to the diamond's overall sparkle and appeal.

The Future of Diamond Cutting

The evolution of diamond cutting hinges on technological advancements and a commitment to ethical and sustainable practices. I'll examine how these elements will shape the future of this fine art, with a focus on enhancing both design and value.

Technological Innovations

Technology is set to play a crucial role in the future of diamond cutting. I'm looking at the integration of automated diamond planning systems and laser cutting tools, which will streamline the cutting process and increase efficiency. These modern techniques will allow for greater precision in cutting, resulting in diamonds with superior brilliance and symmetry. Additionally, technological progression in 3D modeling software will facilitate the creation of unique and intricate designs, potentially raising the value of the finished gemstones.

- Automated Diamond Planning: Enhancing precision and reducing waste.

- Laser Cutting Tools: Increasing accuracy and enabling complex cuts.

- 3D Modeling Software: Expanding the scope for custom and innovative designs.

Ethical and Sustainable Practices

My attention also focuses on the growing importance of ethical sourcing and sustainability in the diamond industry. Cutting techniques will likely evolve to minimize waste and conserve resources, mapping to the ethical standards that consumers demand. The use of lab-grown diamonds is becoming more prevalent as they offer a more environmentally friendly and ethical alternative to mined diamonds. These synthetic diamonds are identical in structure and appearance to their natural counterparts, yet they provide a more transparent value chain.

- Lab-grown Diamonds: Offering an ethical alternative with less environmental impact.

- Waste Reduction: Adapting cutting methods to conserve raw materials.

The drive towards more ethical production and the embrace of new technologies will revolutionize the way diamonds are cut, creating a future that is both innovative and responsible.

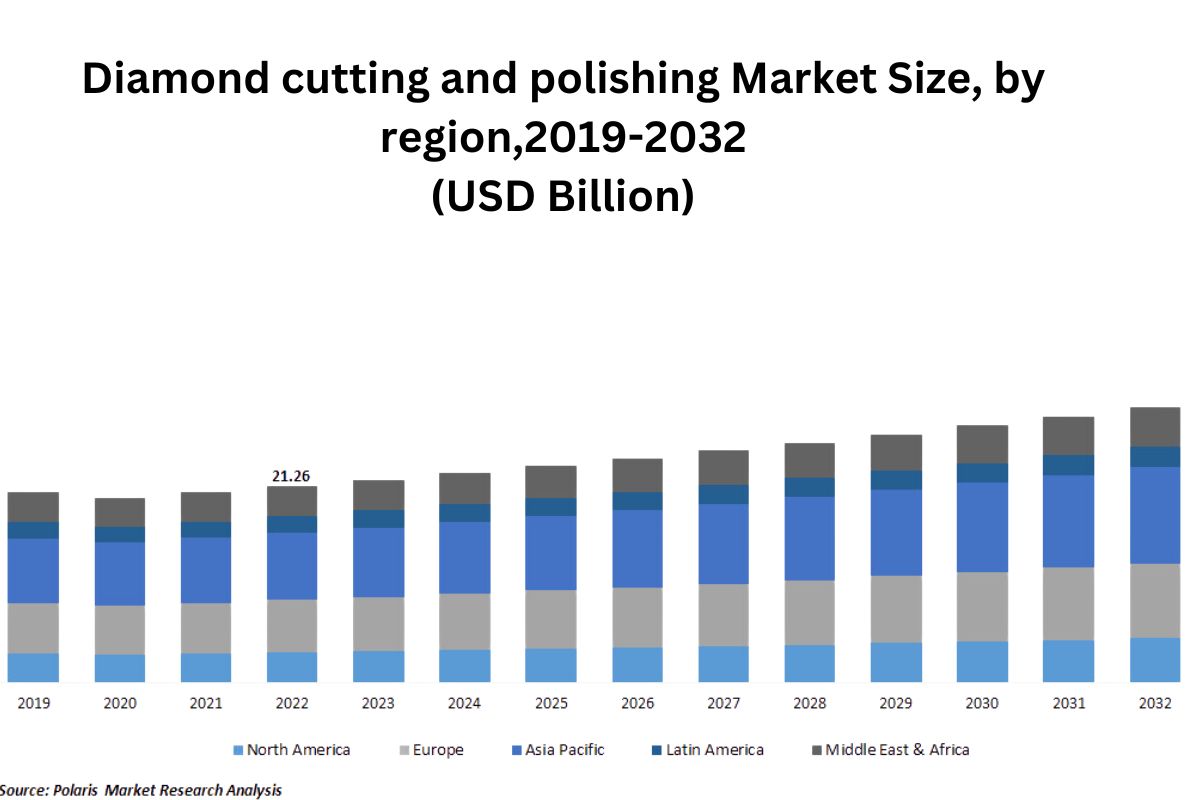

Diamond Cutting Around the World

Diamond cutting is a meticulous art that transforms rough stones into sparkling gems. As an intricate process, it significantly hinges on precision and expertise. Here, we will explore the prominent hubs for this craft and the diverse cultural nuances influencing their techniques.

Major Diamond Cutting Centers

India is the powerhouse of diamond cutting, with cities like Surat leading the charge. An estimated 90% of the world's diamonds are cut and polished here, thanks to a combination of skilled labor and proximity to diamond sources.

- India (Surat): Commands the majority with up to 92% of diamond processing.

- Africa: While not a major cutting center, it is a crucial supplier of rough diamonds.

- United States: Has a notable market, especially for high-end and branded diamond cuts.

- Europe (Antwerp): Although not as dominant as Surat, it remains a key player with a deep heritage in the trade.

Cultural Significance and Techniques

Different regions bring unique cultural influences and cutting styles to diamond processing. The most prevalent cut globally is the Round Brilliant Cut, but the rise of fancy cuts showcases the diversity and innovative progression in cutting techniques.

- Single Cut: Often a starting point for small diamonds, reflecting traditional methods.

- Fancy Cuts: Encompass a variety of shapes like marquise, pear, and heart, influenced by cultural and market demands.

- Indian Diamonds: Reflecting both ancient methods and cutting-edge techniques, Indian cutters are known for their dexterity across various cuts.

In conclusion, India's dominance due to efficiency and voluminous output, the United States' luxury segment, Africa's resource supply, and Europe's historical significance all converge to shape the diamond cutting industry's global landscape.

Buying Tips for Cut Diamonds

When selecting a cut diamond, I consider cut quality paramount since it directly influences a diamond's sparkle, fire, and brilliance. Here are essential factors to ensure my choice is both beautiful and a sound investment:

- Shape: The shape of the diamond sets the foundation for its style. Popular shapes include round, oval, princess, and emerald, each offering a unique reflection pattern.

- Cut Grade: I check the cut grade, which evaluates how well a diamond interacts with light. GIA grades range from Excellent to Poor, and I aim for at least a Very Good grade to ensure optimum light performance.

- Proportions: Proportion refers to the diamond's dimensional balance. Ideal proportions optimize light reflection and refraction.

- Symmetry: I look for diamonds with high symmetry, which ensures uniform light reflection and contributes to the stone's overall brilliance.

- Design: The design and craftsmanship of the cut impact a diamond's value. A well-cut diamond will have a balance between its depth and width, maximizing its ability to reflect light.

- Carat Weight vs. Appearance: Carat weight can influence a diamond's price, but a larger carat weight doesn't ensure a better appearance. A smaller, well-cut diamond can exhibit more sparkle than a larger, poorly-cut one.

- Budget: I balance cut quality with my budget, recognizing that higher cut grades contribute to the diamond's overall beauty and longevity, often making it worth the investment.

In short, I prioritize a diamond's cut quality over size when considering an engagement ring or any diamond jewelry, as a brilliantly-cut diamond will display superior fire and reflection, making it a captivating centerpiece.

The Artistry of Diamond Cutters

I understand that diamond cutting is a meticulous craft, balancing precision and creativity. As a diamond cutter, my role extends beyond shaping a stone; I am an artisan tasked with unlocking each diamond's intrinsic beauty. The process employs advanced techniques to construct facets that capture and reflect light, giving the diamond its signature brilliance.

I often start with the brilliant cut, the most popular due to its unmatched fire and sparkle. This style has numerous facets—usually 58—which are arranged to maximize light return. The art of cutting a brilliant-cut diamond requires a sophisticated understanding of angles and proportions to ensure the maximum brilliance is achieved.

Fancy cuts like the pear shape, oval, marquise, and emerald cut require a distinct approach. Each of these shapes has its own set of challenges. For instance, with the marquise cut, I take extra care to avoid the bow-tie effect—a dark area that can appear in the center. The pear shape demands symmetry, while the oval cut aims for an even distribution of light. The emerald cut belongs to the step cut family, known for its clean lines and elegance, and asks for precision in creating its parallel facets.

- Pear Shape: Symmetry is crucial.

- Oval: Even light distribution.

- Marquise: Avoid the bow-tie effect.

- Emerald Cut (Step Cut): Precision for parallel facets.

The radiant cut is a hybrid, combining the brilliance of a round diamond with the clear lines of an emerald cut, offering a vibrant alternative for those who appreciate both sparkle and form.

Each facet I create is a testament to the craftsmanship and patience required in diamond cutting. The point cut, one of the earliest techniques, has evolved into intricate designs like the modern brilliant cut showcasing our advancement in the craft. Every cut I make aims to enhance the diamond's natural splendor, making my role both an honor and a substantial responsibility.

Technical Aspects of Cutting Diamonds

In the complex process of diamond cutting, my attention to detail is paramount. Each of my cuts aims to enhance a diamond's natural beauty through its angles, facets, and symmetry. The cut quality is crucial as it greatly influences the gem's interaction with light.

Facets are the smooth surface areas of a diamond that I meticulously craft. The number, placement, and angle of these facets are determinants of the stone’s brilliance. For example, a well-cut round brilliant diamond typically has 57 or 58 facets, each meticulously measured and cut.

The table is the large, flat surface on the top of the diamond and is considered when assessing cut quality. A well-proportioned table allows for optimal light reflection. The crown, which is above the girdle, and the pavilion, below it, must have angles and lengths that work in harmony to maximize the reflection and refraction of light.

Girdle thickness can affect a diamond's durability. A very thin girdle makes the stone prone to chipping, while a girdle that is too thick can reduce the diamond's overall beauty.

The pavilion angle and depth are critical for light reflection. These must be precise; if too shallow or too deep, the light escapes from the sides or bottom, resulting in a less luminous diamond.

A correctly cut diamond ensures that light entering through the table reaches the facets and is then reflected back to the viewer's eye. This interplay of light includes two key phenomena: brilliance (white light reflections) and fire (dispersions of color).

The culet is the tiny point at the base of the diamond. While a sharp culet is traditional, modern cuts often feature a small facet at this point to prevent chipping.

The symmetry of these components is crucial for the stone's balance and directly impacts its ability to reflect light effectively, thereby enhancing its sparkle and overall visual appeal.

In summary, my mastery of crafting the crown, pavilion, and every tiny facet, while maintaining an ideal symmetry and proportion, results in diamonds of unparalleled brilliance and quality.

Also Read

Frequently Asked Questions

I've compiled some of the most commonly asked questions about diamond cutting to enhance your understanding of this intricate process.

What are the different techniques used in diamond cutting?

In diamond cutting, techniques such as sawing, bruting (also known as girdling), and polishing transform raw stones into finished diamonds. The method I choose depends on the diamond's characteristics and the desired final shape.

How is the pricing determined for cutting a diamond?

The pricing for diamond cutting is determined by the diamond’s carat weight, the complexity of the cut, and the level of craftsmanship required. I always consider the time investment and the skill of the diamond cutter.

What machinery is commonly used for cutting diamonds?

For diamond cutting, I primarily use specialized saws, laser cutting machines, and scaife, which are rotating polishing disks coated with diamond powder. These tools achieve precision and enable complex cuts.

What distinguishes a quality diamond cut from an inferior one?

A quality diamond cut exhibits optimal proportions, symmetry, and polish. These characteristics ensure maximum brilliance, fire, and scintillation. Conversely, an inferior cut may result in a less vibrant and attractive diamond.

How do diamond cutters shape diamonds into unique cuts?

I shape diamonds into unique cuts by meticulously planning each facet and cut to bring out the stone's individual beauty. This often involves creative interpretation and innovative techniques to create distinctive and captivating shapes.

Which countries are known for their expertise in diamond cutting?

India, specifically a city called Surat, is known for processing a vast majority of the world's diamonds. Other countries renowned for diamond cutting expertise include Belgium, Israel, and the United States.

Checkout some of our top collections:

Leave a comment

Please note, comments must be approved before they are published.