What is Used to Cut Diamonds: Unveiling the Precision Tools Behind the Sparkle

Diamonds, known for their unparalleled hardness and sparkling beauty, present a unique challenge when it comes to shaping them into the dazzling gems that adorn jewelry.

My understanding of diamond cutting is that it's an art that blends precision engineering with skilled craftsmanship.

The process begins with a rough stone, which must be carefully assessed to maximize its potential. As I've learned, each diamond's path from rough to refined is as unique as the gem itself.

A range of specialized tools is employed to cut diamonds. Traditionally, a diamond saw, which incorporates a blade coated in diamond dust, has been indispensable due to its ability to cut through the stone's hard surface. I am also aware of the advancements that have brought lasers into the mix, providing a contactless cut that’s especially useful for diamonds with jagged configurations.

The initial shaping is often followed by detailed facet cutting, which makes the diamonds catch and reflect light in those mesmerizing patterns that characterize the stone's allure.

My understanding of diamond cutting is complemented by the meticulous process of polishing, which gives the diamond its final touch of brilliance.

This is achieved through a rotating arm and a spinning wheel, allowing for the smooth and reflective facets to emerge on the diamond's surface. The process overall is not just a matter of aesthetics, but is deeply rooted in geometry, light physics, and precise workmanship to ensure the cut enhances the stone's innate radiance.

The Essentials of Diamond Cutting

When I approach the craft of diamond cutting, I consider the intricate interplay of technical precision and artistic dexterity. It's a challenging process that transforms a rough diamond into a brilliantly faceted gem.

Understanding Diamond Anatomy

- Structure: Diamonds are renowned for their complex crystalline structure composed of carbon atoms linked in a rigid lattice. This structure imparts diamonds with their characteristic hardness, enabling them to retain well-defined shapes once cut.

- Carat: One crucial aspect I focus on is the carat weight, which signifies the diamond's mass; one carat equates to 200 milligrams. Throughout the cutting process, maintaining an optimal balance between carat weight and cut quality is vital.

Diamond Hardness and Cleaving

- Hardness: With a rating of 10 on the Mohs scale, diamonds are the hardest natural material on Earth. This hardness allows me to cut or polish a diamond exclusively with another diamond.

- Cleaving: This method involves splitting a rough diamond along its natural planes of weakness. Cleaving is a skillful operation that I perform with precise strokes to ensure minimum loss of material and maximize the potential of the rough stone.

Grading and Evaluating Rough Diamonds

- Rough Diamond Evaluation: Before cutting, I evaluate the rough diamond, assessing its size, color, and clarity to anticipate the quality of the final cut. This evaluation influences decisions like the shape and number of facets, directly affecting the diamond's brilliance and value.

- Grading: Diamonds are graded based upon their response to light—their brilliance, fire, and scintillation. These characteristics are greatly influenced by the quality of the cut and are essential considerations in the diamond process.

Cutting Techniques and Tools

In my experience, cutting a diamond requires precision, skill, and the right tools to ensure that each cut maximizes the stone's innate beauty.

The process utilizes a combination of traditional methods and modern technology to shape and polish this hardest of minerals.

Sawing and Shaping

When I begin the cutting process, sawing is typically the first step.

I use a diamond saw or a laser to slice the rough diamond into separate pieces. A diamond saw is embedded with diamond dust to make it abrasive enough to cut through the stone. Sawing does not involve cleaving or fracturing but rather a gentle and controlled separation.

- Tools Used:

- Diamond Saw

- Copper Blade

- Diamond Dust (as an abrasive)

Bruting and Polishing

After sawing, bruting is what gives the diamond its basic shape.

As a diamond cutter, I use another diamond to grind against the rough stone, spinning it on a lathe, and gradually shaping it into a rounded form.

Polishing then brings out the diamond's luster. For this step, I use a polishing wheel coated with an abrasive diamond powder, meticulously crafting each facet to achieve maximum brilliance.

- Bruting Tools:

- Diamond-to-Diamond Contact Wheel

- Polishing Tools:

- Polishing Wheel

- Diamond Powder

Laser Cutting

For intricate cuts or to achieve complex designs, I often turn to laser cutting.

The high-precision lasers can create accurate and minute cuts which are impossible to make with traditional sawing. Lasers don't cause the diamond material to fracture, which means I can make close cuts without the risk of breaking the stone.

- Laser Specifications:

- High-precision

- Minimal waste

- No fracture risk

Diamond Shapes and Styles

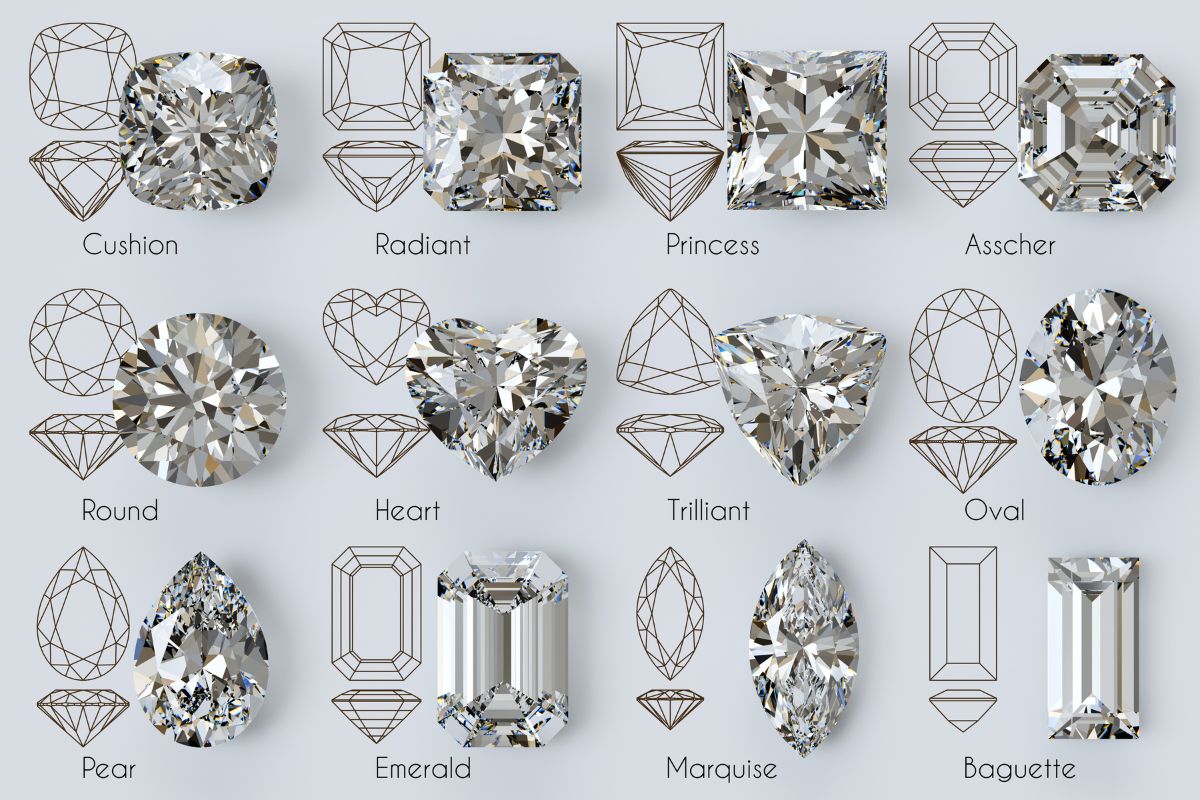

In my extensive understanding of gemology, I recognize that diamond shapes and styles significantly influence their appearance and brilliance. They are typically divided into standard round and brilliant cuts and a variety of fancy shapes, each with unique characteristics that cater to diverse preferences.

Round and Brilliant Cuts

Round cut diamonds, also known as round brilliants, are the most popular diamond shape for their exceptional ability to maximize light reflection, thus enhancing sparkle. This cut features a standard of 58 facets, which include the culet (the bottom tip of the diamond), the table (the flat top), and a symmetrical arrangement of facets that optimally handle light.

- Brilliant Cuts:

- Typical Facet Count: 58

- Prominent Features: High brilliance and sparkle

Fancy Diamond Shapes

Beyond the classic round, there are several fancy diamond shapes, each offering a distinct look and a specific character.

-

Princess Cut: Known for its sharp angles and a square or rectangular shape, the princess cut is a modern favorite. Its facets are arranged to maximize the diamond's fire, much like a round brilliant.

- Shape: Square or rectangular with pointed corners

-

Cut Style: Modified brilliant

-

Cushion Cut: With rounded corners and large facets, the cushion cut combines a square cut with rounded edges, resembling a pillow, hence its name.

-

Emerald Cut: Characterized by a rectangular shape and a unique step cut, this cut's long, linear facets bring a sophisticated elegance with less brilliance but strong flashes of light and color.

-

Pear Cut: A combination of round and marquise shapes, a pear cut, also called a teardrop, is rounded on one end and pointed at the other, creating an elegant and slenderizing effect on the finger.

Final Considerations for Diamond Cut Quality

In my experience, the cut quality is crucial because it enhances a diamond's beauty by maximizing its brilliance, fire, and sparkle.

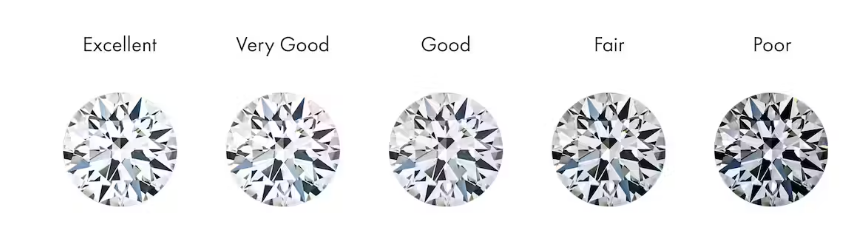

Assessing Cut Grades

The grading of a diamond's cut is a precise art that directly influences its ability to refract light and exhibit radiance.

Cut grades, ranging from 'Excellent' to 'Poor', provide insight into the interaction of light with the diamond's facets. I consider symmetry and workmanship crucial in this assessment, as they affect how light travels within the diamond, creating the visual effects that one values, such as scintillation and sparkle.

- Excellent: Optimal light reflection, producing maximum brilliance and fire.

- Good: Adequate reflection of light, offering a fair amount of brilliance and fire.

- Fair: Compromised light reflection, resulting in reduced brilliance.

- Poor: Inadequate light reflection, leading to minimal brilliance.

Factors Affecting Brilliance and Fire

The quality of a diamond cut hinges on several factors that I always inspect meticulously:

- Brightness: The total light reflected from a diamond.

- Fire: The dispersion of light into the colors of the spectrum.

- Scintillation: The pattern of light and dark areas and the flashes of light, or sparkle when a diamond moves.

- Symmetry: How precisely the facets align and intersect.

- Proportion: How well the various parts of a diamond are sized and shaped in relation to each other.

The Diamond Cutting Process

| Stage | Description |

|---|---|

| 1. Planning | Selection of rough diamond based on size, shape, and potential for maximizing value. Planning the cut to minimize waste and maximize yield. |

| 2. Cleaving or Sawing | Using a diamond saw or laser to split the rough diamond along its natural cleavage planes, creating smaller pieces called "cleavages" or "sawables." |

| 3. Bruting or Girdling | Shaping the rough diamond into a basic round shape by grinding against another diamond, known as a bruting wheel, to create the diamond's girdle. |

| 4. Faceting | Creating the diamond's facets by grinding and polishing each facet individually to maximize brilliance, fire, and scintillation. |

| 5. Inspection | Thorough examination of the diamond to ensure symmetry, proportions, and absence of defects or inclusions that may affect its beauty and value. |

| 6. Certification | Obtaining certification from reputable gemological laboratories to authenticate the diamond's quality, including its cut, color, clarity, and carat weight. |

| 7. Final Polishing | Final polishing to remove any remaining surface imperfections and enhance the diamond's brilliance and luster, achieving the desired finish. |

| 8. Grading | Grading the finished diamond based on established criteria to determine its quality and value, including the 4Cs: cut, color, clarity, and carat weight. |

| 9. Marketing and Sale | Marketing the polished diamonds to retailers or consumers, either independently or through diamond trading platforms, auctions, or jewelry stores. |

When I cut a diamond, I make sure that precision guides each phase, from planning to a final inspection. My expertise allows me to transform a rough diamond into a stunning gem through meticulous steps that define its cut grade and maximize its brilliance.

Planning and Marking

In the planning stage, I carefully assess the rough diamond's characteristics to decide on its final shape and size. My focus is on maximizing carat weight while preserving the diamond's innate beauty.

By marking the diamond with absolute accuracy, I outline the intended cuts. I consider factors like inclusions and the natural grain of the stone to achieve the perfect cut.

Cleaving and Sawing

Depending on the rough diamond's structure, I either cleave or saw it into separate pieces.

Cleaving involves splitting the diamond along its natural grain using a sharp blow from a cleaving iron. Sawing, however, requires the use of a laser or a diamond-edged saw to cut through the diamond regardless of grain direction.

I always apply these techniques with the utmost care, knowing that each decision is crucial for shaping the gem's final appearance.

Faceting and Final Inspection

In the final steps, I create the facets of the diamond using a precision cutting wheel. My goal is to perfect each angle to optimize light reflection within the diamond, thereby enhancing its fire and brilliance.

During faceting, I systematically polish the diamond to ensure each facet is smooth and reflective. After exhaustive polishing, I carry out a thorough inspection to confirm that the diamond meets the exacting standards of the envisioned cut grade.

Advanced Considerations in Diamond Cutting

In diamond cutting, the precision of the equipment and a deep understanding of the gem's molecular structure are paramount. These two elements influence how effectively a diamond's natural beauty will be revealed.

Technological Advancements in Equipment

The recent advancements in diamond-cutting equipment have significantly bolstered my ability to shape these hard substances.

I now use a diamond saw, which is a specialized tool for cleaving and sawing the rough diamond, reducing potential waste. Diamond dust is often incorporated onto the cutting edges to enhance their effectiveness.

Moreover, the use of phosphor bronze has improved the lathe machines, which provides the necessary rotation for shaping diamonds.

- Diamond lathe equipment: Essential for shaping with high precision.

- Grinding wheels: Coated with diamond dust, these grind the diamond to the desired shape.

The grinding process requires meticulous control as the smallest error could cause a structural weakness in the final product. By employing precision tools, I ensure that each facet is cut to perfection, reflecting light in the most breathtaking manner.

Understanding Diamond's Molecular Structure

My knowledge of the isometric system, which describes the molecular structure of diamonds, plays a crucial role in my cutting technique.

This crystalline structure comprises carbon atoms arranged in a particular pattern that influences where potential weaknesses, like nodular lumps, might be.

- Molecular structure identification: Crucial in assessing where to cut to avoid structural weaknesses.

- Custom equipment usage: Specifically designed to handle the unique properties of diamonds.

Understanding the isometric system allows me to precisely target areas that will produce the most brilliant and valuable gems. It's this combination of advanced equipment and molecular insight that enables gem cutters like me to turn rough stones into stunning, sparkling treasures.

The Market and Diamond Valuation

When evaluating diamonds, I closely consider how the cut and carat weight impact their market value. These factors are crucial in determining the beauty and ultimately the price of the gem.

Impact of Cut on Diamond Value

Cut is arguably the most significant aspect in diamond valuation. It's the cut that unleashes a diamond's beauty, allowing it to sparkle and capture the light.

A well-executed cut maximizes the reflection and refraction of light inside the diamond, enhancing its brilliance.

Meanwhile, diamond cutters must consider the proportions, symmetry, and polish to achieve an optimal cut. Typically, the scale for grading cut quality ranges from Excellent to Poor.

Diamonds with a rating of Excellent or Very Good often fetch higher prices due to their superior brilliance compared to diamonds with a lower cut grade.

Carat Weight and Size Relevance

Carat weight directly influences a diamond's value and size perception, with prices increasing substantially for higher-weight diamonds.

Carat refers to the weight of the diamond, where one carat is equivalent to 0.20 grams.

The size of a diamond is an important consideration for a diamond purchase. However, it's important to note that two diamonds of equal carat weight can have significantly different values depending on the quality of the cut, color, and clarity.

A higher carat weight combined with a high-quality cut results in a gem that displays more sparkle and aesthetic appeal. My focus is on a balance between carat size and the quality of the cut to optimize the diamond's beauty and value.

Also Read

Frequently Asked Questions

In this section, I will answer some of the most common inquiries regarding the intricacies of diamond cutting, a process that blends artistry and technological precision to transform rough diamonds into exquisitely faceted gems.

What materials are traditionally necessary for cutting diamonds?

Traditionally, diamond cutting required the use of other diamonds or diamond dust. The hardness of diamonds, which is the highest on the Mohs scale, means they can only be scratched or cut by other diamonds.

How do professionals cut and polish diamonds in modern processes?

Professionals now use advanced technological tools such as laser cutting machines and computer-aided design (CAD) to cut and polish diamonds with high precision.

Polishing is done using a diamond wheel coated with diamond powder to achieve a smooth and shiny surface on the cut diamond.

What historical methods were utilized for diamond cutting?

Historically, the diamond cutting process was done by hand, using simple tools like cleaving irons and polishing wheels. The cutter's skill and experience played a significant role in judging the cutting angles and facet arrangements.

Can other substances besides diamonds cut or shape diamond gems?

While diamonds are the hardest naturally occurring material, they can be shaped using high-powered lasers or extremely precise mechanical means, such as specialized diamond-tipped tools.

What specific tools do artisans employ in the diamond cutting industry?

Artisans in the diamond cutting industry use a variety of tools including cleaving and bruting machines, scaif polishing wheels, and laser cutting machines. The scaif is a rotating polishing disk coated with oil and diamond powder, crucial for achieving a diamond's final facet pattern.

Which nations are recognized for their diamond cutting expertise?

Belgium, India, Israel, and Russia are among the nations best known for their diamond cutting expertise. Antwerp in Belgium, particularly, has a long-standing reputation as a world leader in diamond cutting and trade.

Checkout some of our top collections:

Leave a comment

Please note, comments must be approved before they are published.